High Precision Injection YH-850

Injection molding machine research and development

Every year, we invest a lot of human resources in the research and development of injection molding machines. So far we have obtained a number of patents and independent intellectual property rights. We are keen on the improvement of the human-machine interface, the research and development of high-speed injection molding, and the precision injection with stable control on the PC side.

R & D team

Our technical research and development team specializes in data analysis and structural optimization. They are committed to the research and development of computer control systems, hydraulic systems, electrical appliances, etc. In the past few years, we have accumulated a wealth of experience, and so far, it has been fruitful .

We will continue to devote ourselves to the research and development of injection molding machines. We are committed to becoming a leader in the injection molding industry.

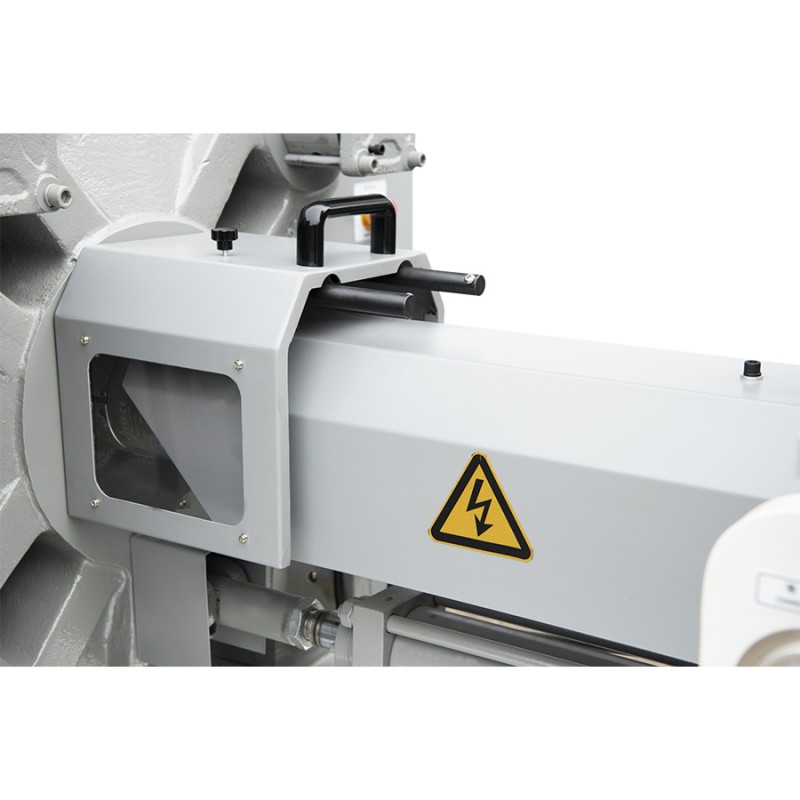

Quality control of all mechanical parts

Our QC team conducts quality control on the machine base, frame and all machine parts. We use CAM to check whether the frame and other parts are deformed before assembly, and check whether the dimensions of all parts are within the tolerance range of the 2D drawing.

| Specification | Unit | YH-850 |

| Injection Unit | ||

| Screw Diameter | мм | 90 |

| 100 | ||

| 110 | ||

| 120 | ||

| Screw L/D Ratio | L/D | 24.4 |

| 22 | ||

| 20 | ||

| 18.3 | ||

| Shot Volume | см3 | 3179.3 |

| 3925 | ||

| 4749.3 | ||

| 5652 | ||

| Shot Weight (PS) | g | 2988.5 |

| 3689.5 | ||

| 4464.3 | ||

| 5312.9 | ||

| Injection Pressure | Mpa | 211 |

| 171 | ||

| 141 | ||

| 119 | ||

| Injection weight(PS) | g/s | 516.1 |

| 637.2 | ||

| 771 | ||

| 917.6 | ||

| Plasticizing capacity (PS) | g/s | 106.8 |

| 131.9 | ||

| 159.6 | ||

| 189.9 | ||

| Scew speed | rpm | 127 |

| Clamping unit | ||

| Clamping stroke | KN | 8800 |

| Platen stroke | мм | 1040 |

| Space Between Tie-bars | мм | 1000*1000 |

| Max. Mould Thickness | мм | 1000 |

| Min. Mould Thickness | мм | 420 |

| Ejector Stroke | мм | 283 |

| Ejector Force | KN | 212.3 |

| Other | ||

| Pump Motor Power | Kw | 37+37 |

| Heating Power | KW | 61 |

| Oli Tank Volume | L | 949 |

| Machine Dimension | M | 10.9.*2.5*2.8 |

| Machine Weight | T | 38 |