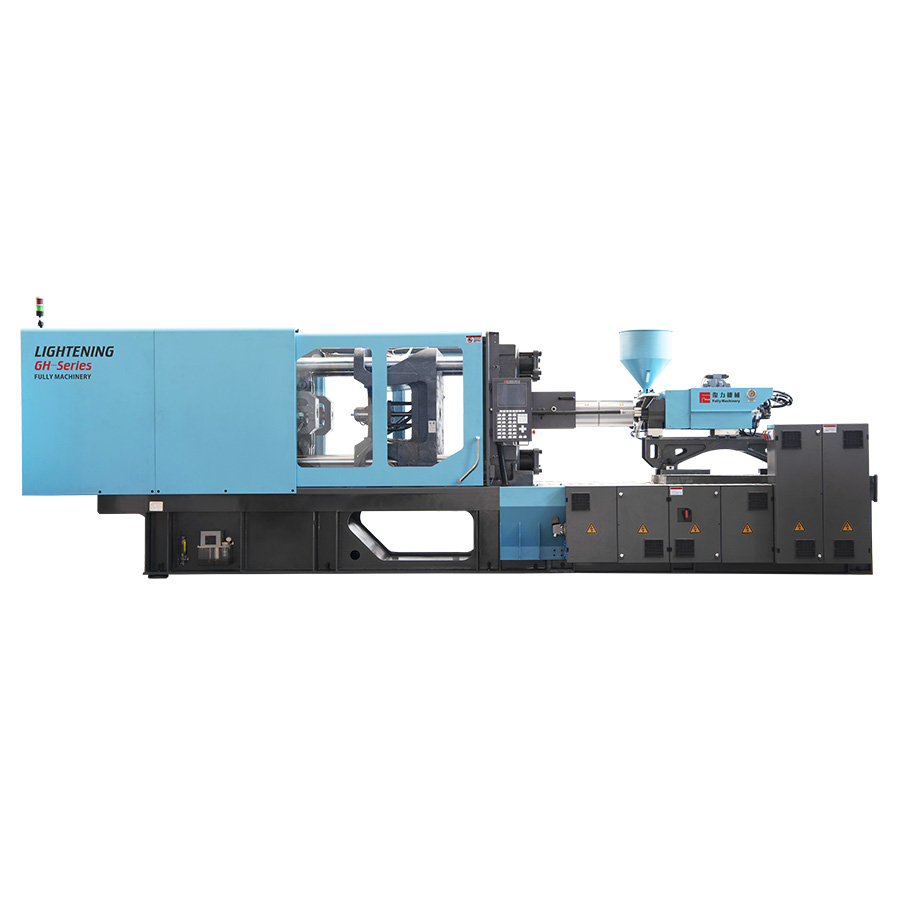

Short Lead Time for Cavity Pressure In Injection Molding - Thin Wall High Speed Injection GH-280 – Beilun

Short Lead Time for Cavity Pressure In Injection Molding - Thin Wall High Speed Injection GH-280 – Beilun Detail:

Injection molding machine testing

We have invested more than 10 different types of injection molds, which are only used to test different types of injection molding machines. Some of these molds are suitable for high-speed injection molding, some require high-precision plastic filling, and some serve molds that have lateral core pulling or are suitable for injection molding of special materials… The test will run on the machine for 24 hours, including the plastic molding process test Will be more than 4 hours…

service

1. Pre-sales service: Our sales and service team help customers choose economical and suitable machine types. And can provide mold design and parameter suggestions.

2. In-sale service: We can help customers design workshop layout, such as the installation of circuits and cooling water. And provide free training for customer employees.

3. After-sales service: We will send engineers to help customers install machines, debug and run ready-made molds, and train workshop workers’ operating skills. During the one-year warranty period, we will guarantee free replacement of damaged parts.

In order to provide better services, we are waiting for more skilled teams to join us in order to provide better services.

|

Project |

Project name |

Unit |

GH280 |

|

|

Injection unit |

SCREW DIAMETER |

mm |

50 |

|

| INJECITON STROKE |

mm |

225 |

||

| SCREW L/D RATIO |

L/D |

25 |

||

| SHOT VOLUME(THEORETICAL) |

CM3 |

420 |

||

| INJECTION WEIGHT(PP) |

g |

378 |

||

|

oz |

13.34 |

|||

| INJECTION PRESSURE |

Mpa |

164 |

||

| DWELL PRESSYRE |

Kg/cm³ |

1675 |

||

| NJECTION SPEED |

mm/sec |

460 |

||

| INJECTION RATE |

cm³sec |

689.5 |

||

| SCREW SPEED |

rpm |

400 |

||

|

clamping unit |

CLAMP FORCE |

Kn |

2800 |

|

| OPEN STROKE |

mm |

560 |

||

| SPACE BETWEEN TIE BARS(V×H) |

mm×mm |

570×570 |

||

| MAX.MOULD HEIGHT |

mm |

600 |

||

| MIN.MOULD HEIGHT |

mm |

240 |

||

| EJECTOR STROKE |

mm |

160 |

||

| EJECTOR FORCE |

Kn |

61.5 |

||

| EJECTOR NUMBER |

N |

5 |

||

|

others |

MAX.PUMP PRESSURE |

Mpa |

23 |

|

| PUMP MOTOR POWER |

Kw |

79.6 |

34.1+55.5 |

|

| HEATING POWER |

Kw |

18.65 |

||

| MACHINE DIMENSION(L*W*H) |

M×m×m |

6.05×1.5×1.86 |

||

| OILTANK CUBAGE |

L |

350 |

||

| MACHINE WEIGHT(ESTIMATE) |

T |

9.7 |

||

Product detail pictures:

Related Product Guide:

With our loaded encounter and considerate services, we have now been recognized as a trustworthy supplier for lots of worldwide consumers for Short Lead Time for Cavity Pressure In Injection Molding - Thin Wall High Speed Injection GH-280 – Beilun , The product will supply to all over the world, such as: Nigeria, Iran, Romania, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.